What is Industrial IoT? A quick guide with IIoT device examples and use cases

Industrial IoT is the use of smart connected devices for large-scale industrial applications. In simpler terms, IIoT is the use of machines to make human jobs easier. So it is no surprise that the term Industrial Internet of Things, or IIoT, is often used interchangeably with Industry 4.0.

The global IIoT market is expected to grow up to USD 1.11 trillion by 2028. This number only tells us that this industry is rapidly growing. But leaves out more crucial questions such as why and how.

What to expect: In this article, we will explore the several ways in which Industrial IoT is being used across the world while talking about its impact on various industries.

What is Industrial IoT (IIoT)?

Industrial IoT uses smart devices such as sensors, meters, or even smart faucets and construction vehicles to automate industrial processes like agriculture, manufacturing, etc.

Given that industrial IoT employs technology to radically improve industrial productivity, it has been hailed as the fourth industrial revolution or Industry 4.0.

The interesting part of this phenomenon, however, is as much cultural as it is economic. When the original industrial revolution took place, most people were understandably worried about losing their jobs to factories. Many artisans and manufacturers who used manual means for production did lose their livelihoods to the industrial revolution. But in the long run, this change created more jobs than it took. (Although the qualitative analysis of this impact is best left to historians.)

Similarly, with IIoT, there are some major concerns over smart devices replacing humans. Fortunately, this industrial revolution comes with a core tenet of collaboration between humans and machines.

Why is IIoT important?

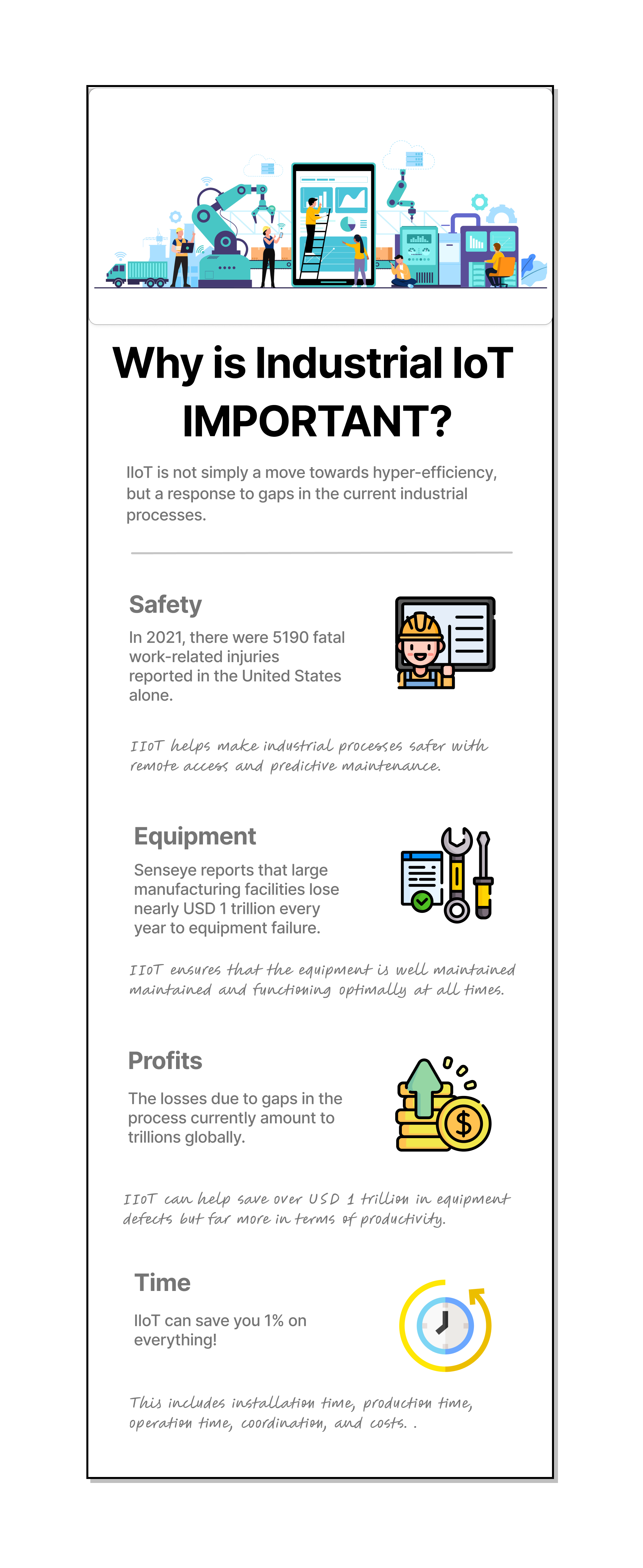

IIoT is not simply a move towards hyper-efficiency, but a response to gaps in the current industrial processes.

In 2021, there were 5190 fatal work-related injuries reported in the United States alone.

Additionally, Senseye reports that large manufacturing facilities lose nearly USD 1 trillion every year to equipment failure. These losses, especially to human lives, are entirely avoidable, and IIoT offers a nifty solution for this.

Let us take a look at the need for IIoT with a smart factory example. Smart factories are manufacturing or similar industrial units that are operated by connected devices such as sensors, smart assembly lines, and other smart equipment.

Improved efficiency and productivity

In a regular factory environment, say a worker needs to turn on every machine on the floor manually and inspect it. This requires far too long in large units. With a smart factory, this can be done with the click of a button on a laptop and the worker only needs to pay attention to the equipment which may not be performing well. Similarly, any equipment in need of maintenance or repair is identified immediately and the downtime is reduced tremendously.

Better accuracy

When something breaks down in a factory unit, it is not apparent right away, especially with complex machinery. When certain equipment are loaded with multiple parts, it is difficult to tell which one is glitching and needs manual inspection to determine the problem.

Smart factories, on the other hand, as equipped with sensors that can identify any breakdowns to the last bolt and save a lot of time and money.

In agricultural settings, remote patches of land can be monitored for accurate status and better yield.

Enhanced safety

Safety is arguably the most important benefit of IIoT. Accidents are not rare in factories, even though there have been efforts to reduce them for decades now. IIoT allows workers to monitor equipment remotely, and almost entirely eliminates the need for manual handling of any machinery. This greatly reduces the risk to any humans working on the floor.

Predictive maintenance, assisted by IIoT, also reduces the chance of breakdown and accidents in industrial settings.

Less busywork

Finally, IIoT is important to improve the human condition. Smart machines take care of a lot of the grunt work which does not require any skills or talent, enabling human resources to be employed in more fruitful tasks. This also improved overall production and returns.

How do Industrial IoT devices work?

Industrial IoT devices work in tandem with the requirements of industry, just as other IoT devices do.

There is a whole IoT architecture that goes into making IIoT devices collect the right data and undertake the right processes.

- The IIoT devices collect data which is shared with the cloud backend via connectivity protocols.

- This data is then processed and shared with the users via a cloud application. This is where devices and data can be monitored, updated, and visualized.

Industrial IoT devices examples in manufacturing include smart meters, barcode scanners, signal lights, and sensors measuring humidity, temperature, and vibration.

Industrial IoT applications and use cases

Industrial IoT is used in several ways, a lot of which is extremely fascinating. Let us take a look at some of the most interesting applications.

Location tracking

Location tracking is one of the key Industrial IoT applications. Businesses can track the location in real time by equipping assets, vehicles, and people with GPS-enabled sensors and devices. For example, in the transportation and logistics industry, IIoT-enabled location tracking allows companies to monitor the movement of goods and vehicles, predict delivery times, and optimize routing to reduce delivery times and improve customer satisfaction.

It reduces the likelihood of misplaced or lost items, and improving supply chain management.

Predictive maintenance

Predictive maintenance is another key benefit of Industrial Internet of Things (IIoT) technology. By equipping equipment with sensors and connected devices, businesses can collect real-time data on equipment performance, enabling them to predict when maintenance is required before a failure occurs. This can reduce unplanned downtime, minimize repair costs, and improve overall equipment efficiency.

Warehouse management

By equipping inventory and equipment with sensors and connected devices, businesses can monitor warehouse operations, improve supply chain management, and reduce errors. For example, IIoT-enabled inventory management can track the location of goods within the warehouse, enabling faster and more accurate inventory checks, and reducing the likelihood of misplaced or lost items.

Additionally, IIoT-enabled warehouse management can improve equipment utilization by detecting potential issues with warehouse equipment, scheduling maintenance proactively, and reducing downtime.

Energy consumption optimization

Energy consumption optimization is a crucial area where the Industrial Internet of Things has transformed operations. By collecting real-time data on energy consumption, businesses can optimize energy usage and reduce waste. For example, in the manufacturing industry, IIoT-enabled energy management can monitor energy consumption, identifying areas of inefficiency and implementing corrective measures to reduce energy usage.

Environmental and worker safety

Environmental and worker safety are critical concerns for businesses, and the IIoT has played a significant role in improving safety in hazardous environments. By securing equipment, vehicles, and workers with sensors and connected devices, businesses can monitor safety in real-time, identifying potential hazards and taking preventive measures to avoid accidents. For example, IIoT-enabled safety monitoring can detect gas leaks, equipment malfunctions, and other safety hazards, alerting workers and supervisors before an incident occurs.

Furthermore, IIoT can also monitor the environmental impact of business operations, enabling businesses to reduce waste and improve sustainability.

How is IIoT different from other types of IoT?

There are two major schools of thought when it comes to defining IIoT. One being that IIoT devices are not very different from other IoT devices, and work in a similar fashion. The only difference is that IIoT devices collect a wide range of data at a much larger scale than personal IoT devices. For instance, an agricultural field may have thousands of sensors, actuators, trackers etc. The scale of connected device usage is what sets IIoT apart from IoT.

The other school of thought posits that IIoT is simply IoT in an industrial setting i.e. manufacturing. While this definition is limiting, it is the most widely accepted one.

But in all honesty, industrial IOT applications are not restricted to manufacturing anymore so as the industry evolves, we need to keep an eye out for a more refined definition of Industrial IoT.

Security considerations and challenges while adopting IIoT

The Industrial Internet of Things (IIoT) refers to interconnected sensors, instruments, and other devices networked together with industrial applications, including manufacturing and energy management. While IIoT offers numerous benefits such as increased efficiency and productivity, it also presents a unique set of security considerations and challenges.

- Larger Attack Surface: With the integration of countless devices, the attack surface expands significantly, offering more entry points for potential attackers.

- Legacy Systems: Many industrial environments use legacy systems which weren't designed with modern connectivity or security in mind. Integrating IIoT with these systems without proper security can expose them to threats.

- Real-time Operational Requirements: Many IIoT systems require real-time operation and any delay (even if it's due to security checks) can impact processes and cause disruptions.

- Physical Safety Risks: Unlike traditional IT systems, compromised IIoT systems can pose real-world safety risks. For example, a hacked smart grid can lead to power outages, or a tampered industrial robot can pose physical dangers to workers.

- Data Integrity and Reliability: Ensuring the integrity of data in IIoT systems is crucial. Incorrect data can lead to wrong decisions, affecting both efficiency and safety.

- Lack of Standards: The IIoT landscape is evolving rapidly, and universally accepted security standards and practices are still in development, leading to inconsistency in security measures.

- Resource Constraints: Some IIoT devices are resource-limited and can't run advanced security protocols or software, making them vulnerable.

- Complex Supply Chains: Industrial components often have complex supply chains, introducing multiple points where security breaches or vulnerabilities can be introduced.

- Remote Access Challenges: IIoT solutions may require remote access for maintenance or updates, and this can be an entry point for attacks if not properly secured.

- Insider Threats: Given the critical nature of many industrial processes, insider threats – whether accidental or malicious – can have significant impacts.

- Data Privacy Concerns: IIoT systems collect vast amounts of data, which can sometimes include personal or sensitive information. Ensuring this data remains private and compliant with regulations is challenging.

- Interoperability: IIoT involves a combination of various devices, platforms, and systems. Ensuring they all work seamlessly together without introducing vulnerabilities is a significant challenge.

- Long Device Lifespans: Industrial devices often have long lifespans. Over time, they might become outdated in terms of security, yet they remain in operation, creating vulnerabilities.

- Lack of Awareness and Training: The workforce might not always be adequately trained or aware of the security protocols and risks associated with IIoT, leading to inadvertent breaches.

- Evolving Threat Landscape: As with all connected technologies, the threat landscape for IIoT is continually evolving, requiring constant vigilance and updates.

To address these challenges, organizations need a comprehensive approach that includes risk assessments, continuous monitoring, regular updates and patches, employee training, and collaboration with vendors and other stakeholders in the IIoT ecosystem.

Final Thoughts

The Industrial Internet of Things (IIoT) is a powerful technological advancement that has revolutionized several industries, and as Industrial IoT applications continue to evolve, it will play an increasingly important role in shaping the future of various industries.

At Bytebeam, we are always looking at the potential applications of our favorite technologies. If you would like to join us on this journey, subscribe to our blog and learn more about the IoT industry every week.

Frequently Asked Questions

What is the meaning of IIoT?

IIoT stands for the Industrial Internet of Things. It refers to the integration of connected sensors, devices, and machinery in industrial settings like factories and power plants, allowing them to communicate and share data to improve efficiency and automation.

What is IIoT and its application?

Industrial IoT applications involve connecting industrial equipment and devices to collect and analyze data. This enhances efficiency, maintenance, and automation in sectors like manufacturing, energy, and transportation.

What is the difference between IoT and IIoT?

IoT (Internet of Things) refers to everyday connected devices like smart thermostats and wearables. IIoT (Industrial Internet of Things) focuses on industrial equipment like machinery in factories or energy grids, aiming to improve efficiency and operations in industrial settings.